Root Cause Analysis of Power Supply Unit Failure

What Happened?

This case came from an Irish company who manufactures electrical control systems, using off-the-shelf components. An issue had arisen in one site, due to the apparent failure of a power supply unit. The system had been installed some months previously, and was operational for only a short time before failure. I was asked to determine the root cause of the failure. I was provided with the failed unit, and information about the unit and it’s role within the larger electrical control system.

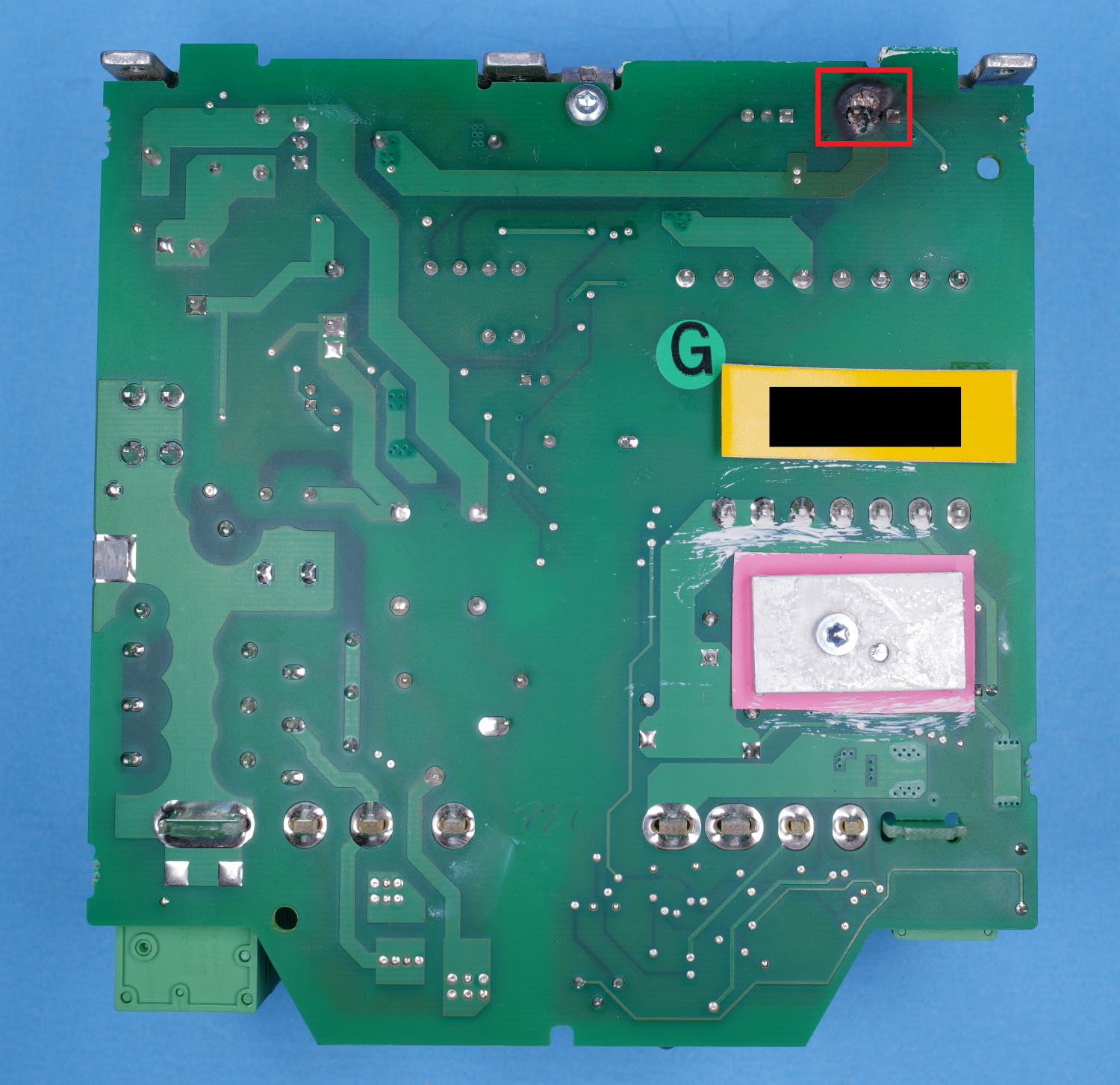

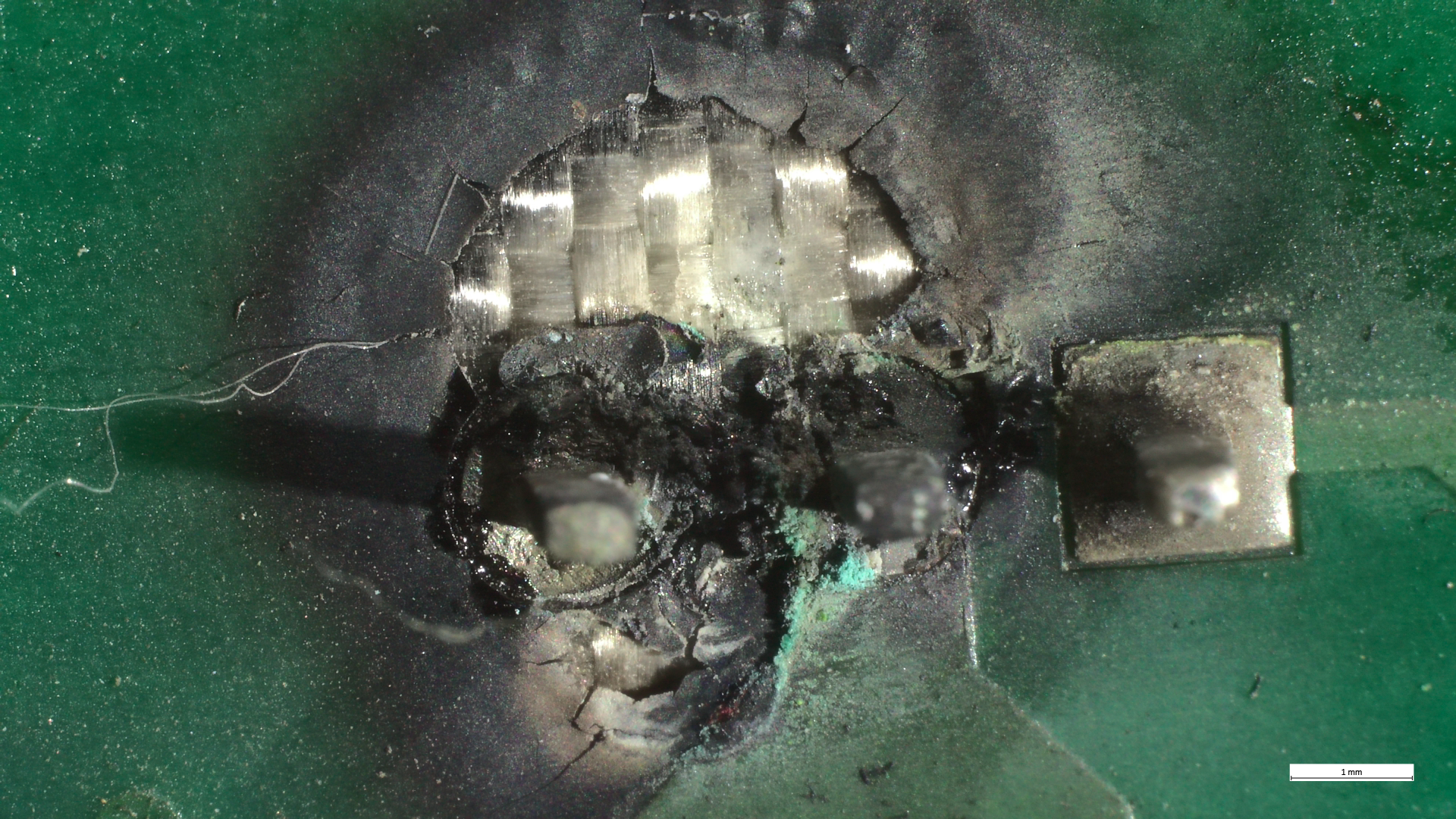

When I opened the unit, the issue was immediately evident - a section of the printed circuit board had been discoloured black, as though the circuitry had been scorched by heat. This discolouration was partss of the power circuit, components which can carry significant electrical current and which may produce significant heat that must be controlled correctly. So we had an idea of what had happened, but we still had to find out why.

How did we analyse it?

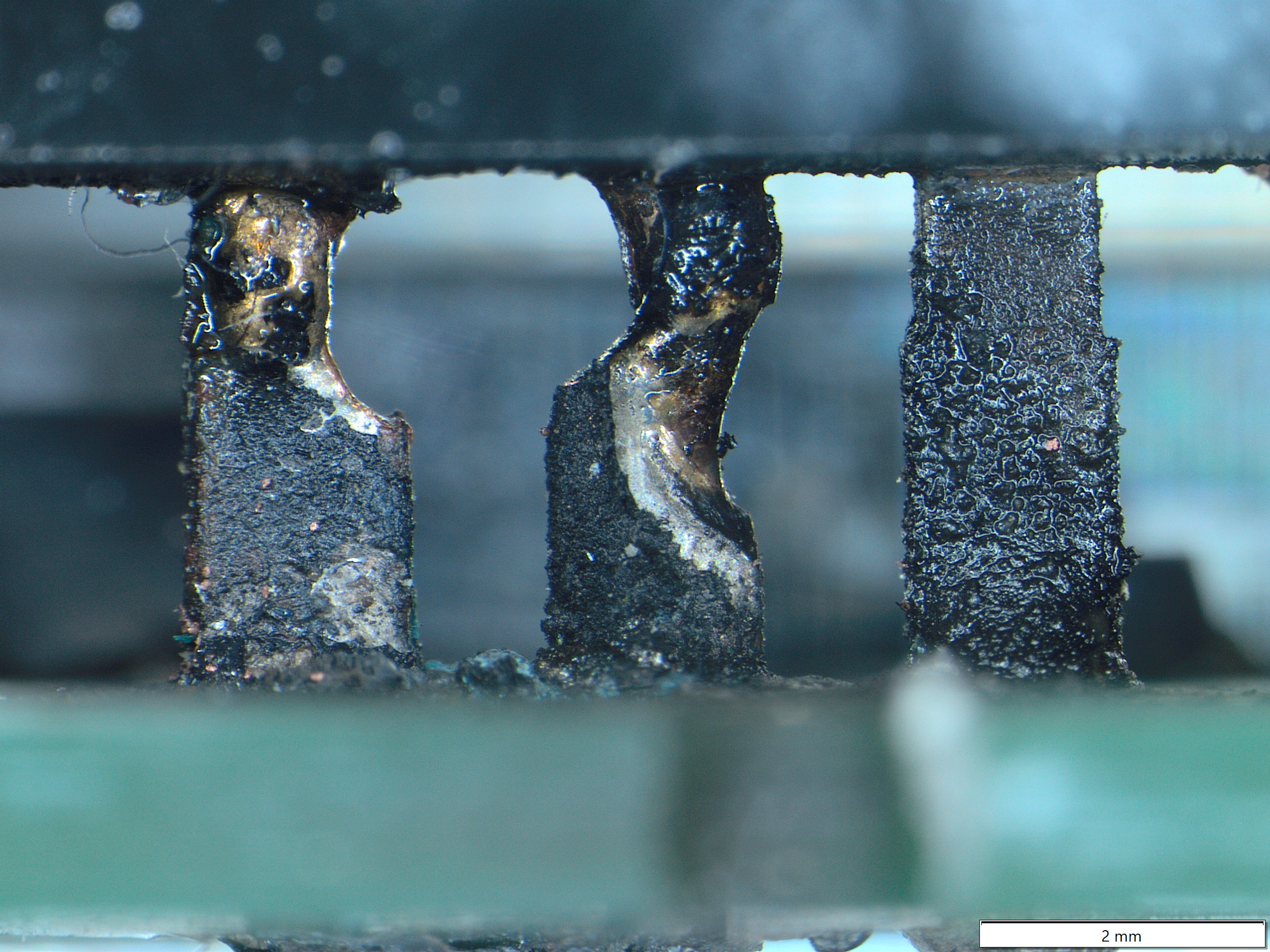

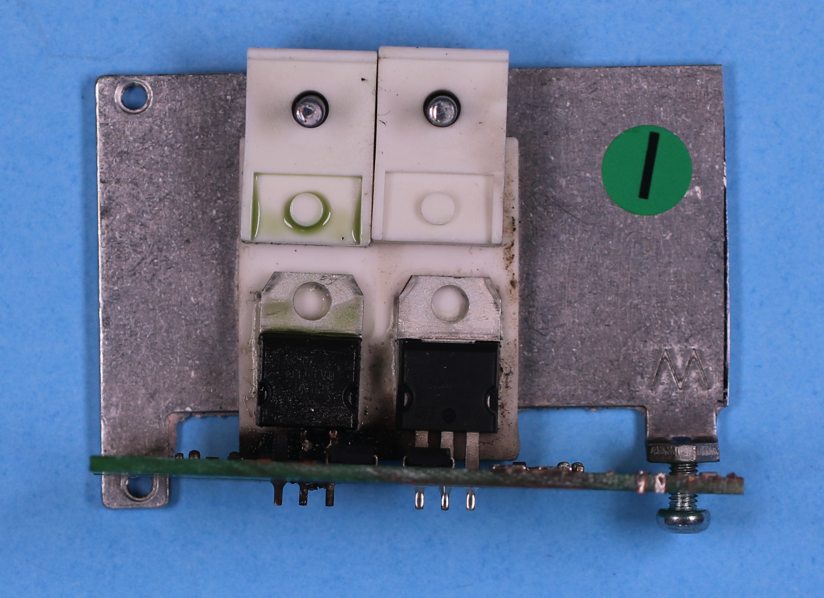

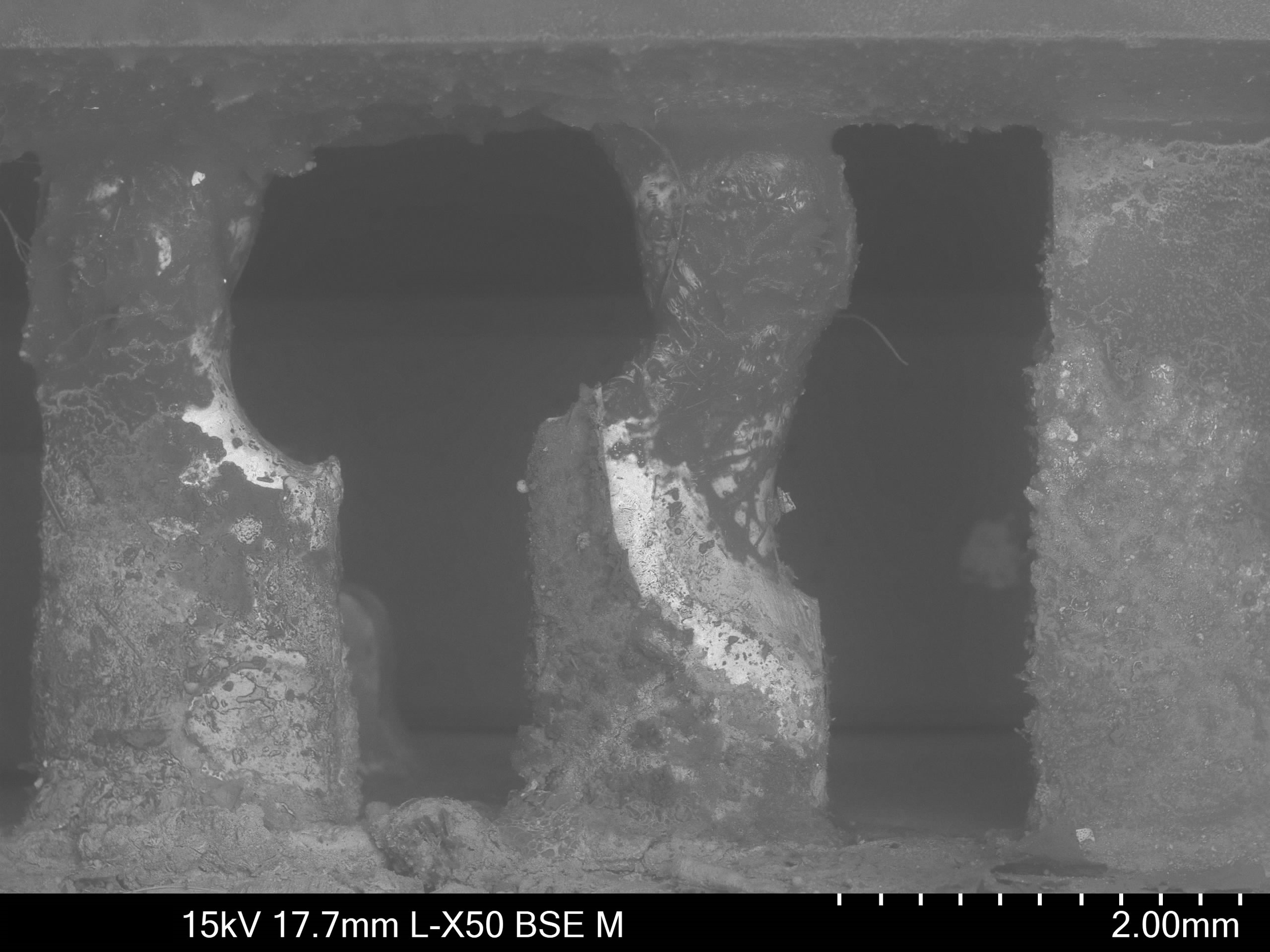

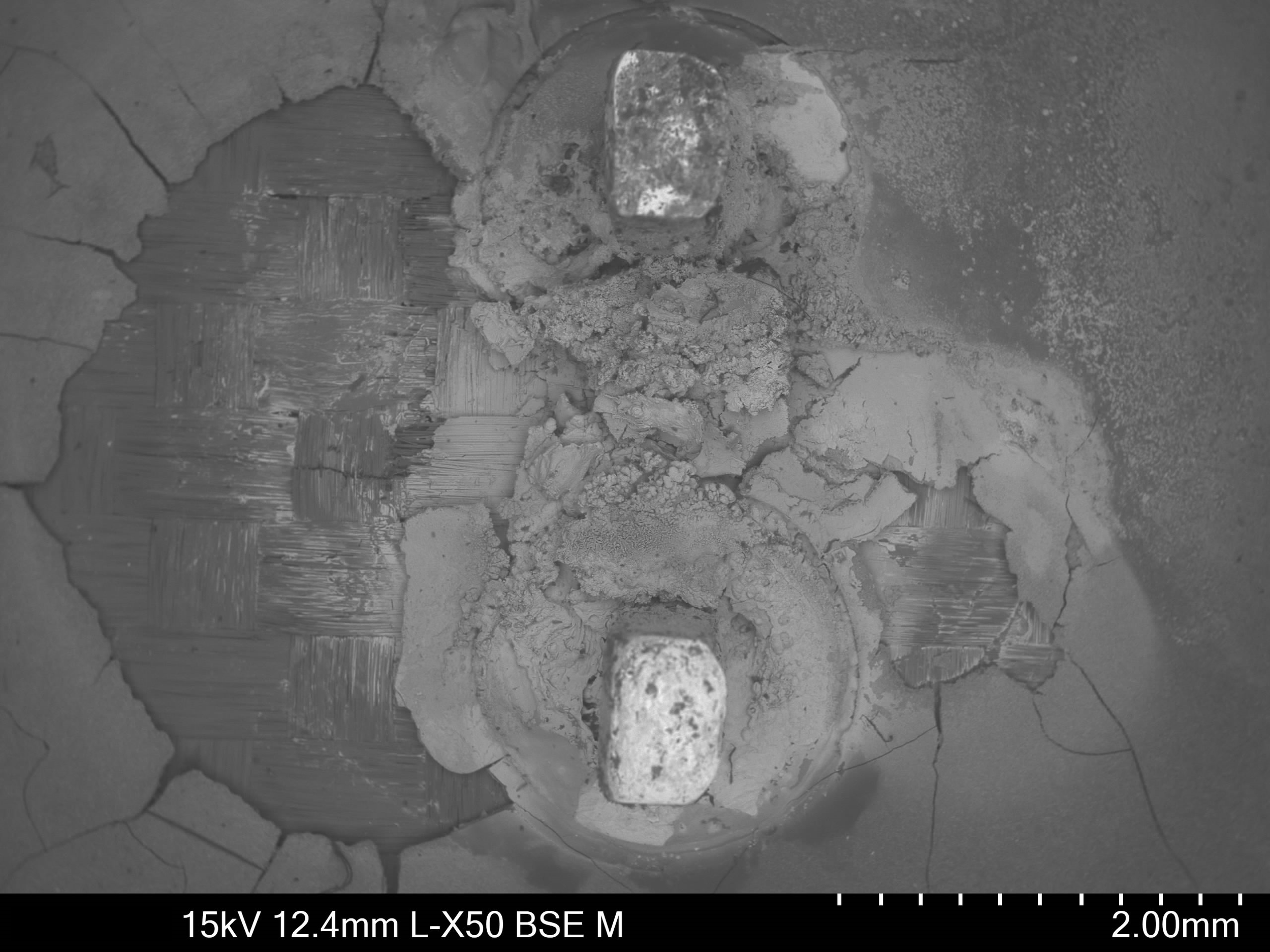

Using a precision micro-cutter, I extracted a section of the printed circuit board in the vicinity of the discoloured area, to perform an examination of the discoloured parts. The discolouration was centred around the legs of a transistor which formed part of the power circuit, and a ceramic heat sink to which the transistor was attached. The legs of the transistor were covered a dark, sticky, unknown substance, and had deformed siginficantly as though a large bite had been taken out of the previously straight leg. Interestingly, there were two transistor/heat sink components adjacent to each other, but only one of these was showing discolouration. The heat sink showing discolouration was disassembled, and a greenish liquid was found within the heat sink, pooling around the point of contact with transistor.

At this stage, a theory was starting to form. We had observed what appeared to be thermally induced damage in the vicinity of a component of the power circuit, which can generate heat due to the current flowing through it. We had observed liquid in the interface between the transistor and the heat sink, which would affect how heat is conducted from the transistor to the heat sink. A link between the two was plausible, but it didnt explain everything. Why was the printed circuit board scorched in some areas, but totally stripped away in others? What was the unknown substance the transistor legs covered in? What was the green liquid, and how did it get inside the heat sink? Clearly, more analysis had to be done.

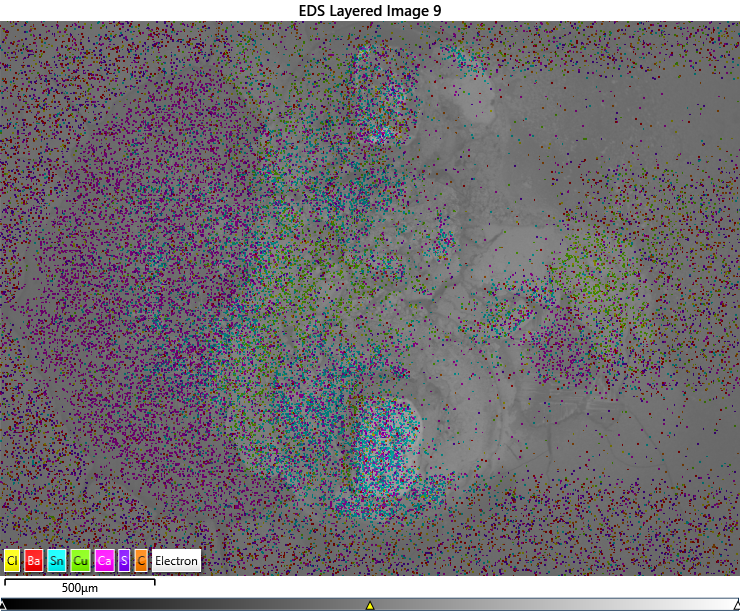

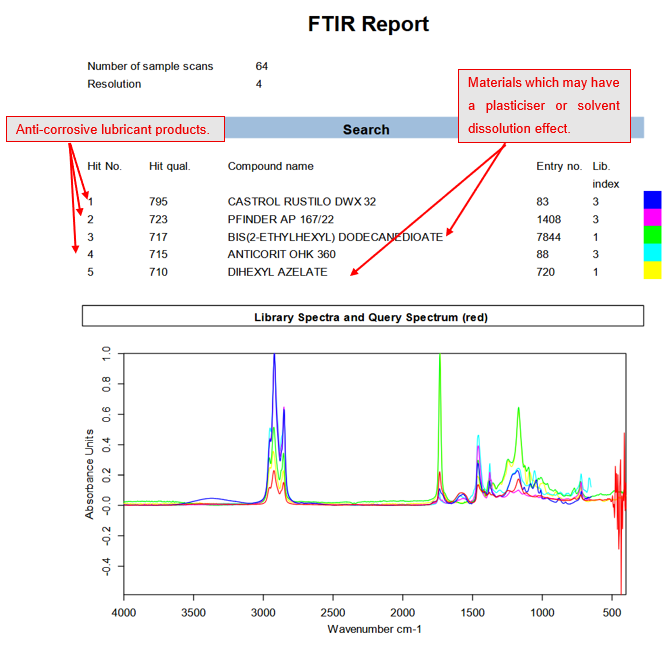

The transistor legs, the printed circuit board, and the green liquid were all subjected to materials analysis. The materials analysis used a combination of Scanning Electron Microscopy (SEM) and Energy Dispersive X-ray Spectroscopy (EDS) for the transistor and printed circuit board, and Fourier Transform InfraRed Spectroscopy (FTIR) for the liquid.

What was the resolution?

To briefly summarise the complex knot of findings, the FTIR analysis identified the green liquid found within the heatsink to be some form of anti-corrosive lubricating spray, and SEM/EDS confirmed this lubrication liquid had coated the legs of the transistor and the printed circuit board in vicinity of the transistor legs, where it appeared to have had a dissolving effect on the PCB. When the heatsink is assembled, a small gap is left, through which the sprayed lubricant entered. Sitting in the interface between the hot transistor and the heatsink, the liquid prevented effective heat transfer between the two, leading to a build-up of heat in the transistor. As the liquid slowly dripped down along the legs of the transistor, it slowly came into contact with the printed circuit board surface, causing a slow dissolution of the surface. The built-up heat caused blackening of the liquid, and eventual failure of the component.

I prepared an Expert Technical Report of my finding, explaining the sequence of events and the effects they had. One question still remained, which I could not answer: how or why was the lubricant sprayed on in the first place? That question remains unanswered, as there was no specification for the spray lubcicant to be used, and none of the maintence staff have any records of such use. Unfortunately, due to the nature of the site with many different contractors and sub-contractors, we will likely never know exactly what happened to cause the power supply unit to be exposed to the material, but at the very least this issue could be prevented in the future.

Do you have a baffling mystery to be solved? Or maybe just a peculiar puzzle? For a science-supported, evidence-based Expert Opinion, be sure to Contact Us today!