Insulation Evaluation Part 2: Spray-Injected Foam

What Happened?

In our last Case Study, we discused the evaluation of rigid board type foam insulation. The discussion now continues, focusing instead on spray-injected type foam insulation. This type of insulation is often used to retro-fit houses and buildings, and is installed by mixing together a very specific recipe of chemicals, and injecting the reactive liquid mixture into the cavities within the wall. The liquid expands to fill the space, then cures and hardens. The preparation of the chemical mixture and the process of injecting it into the walls must follow an exacting procedure, and installers of such systems often must receive specific training or certification to perform this installation. Too much of one material, or not heating to the correct temperature, or injecting too much material, can have disastrous consequences for the walls its injected between,

In one such case, a homeowner was seeking to improve the thermal efficiency of their house through cavity insulation, and sought a spray-injection foam insulation system. A local company was identified, who held the correct certificates and approvals. Following a site-inspection, the wall cavities were injected with an expanding foam insulation system.

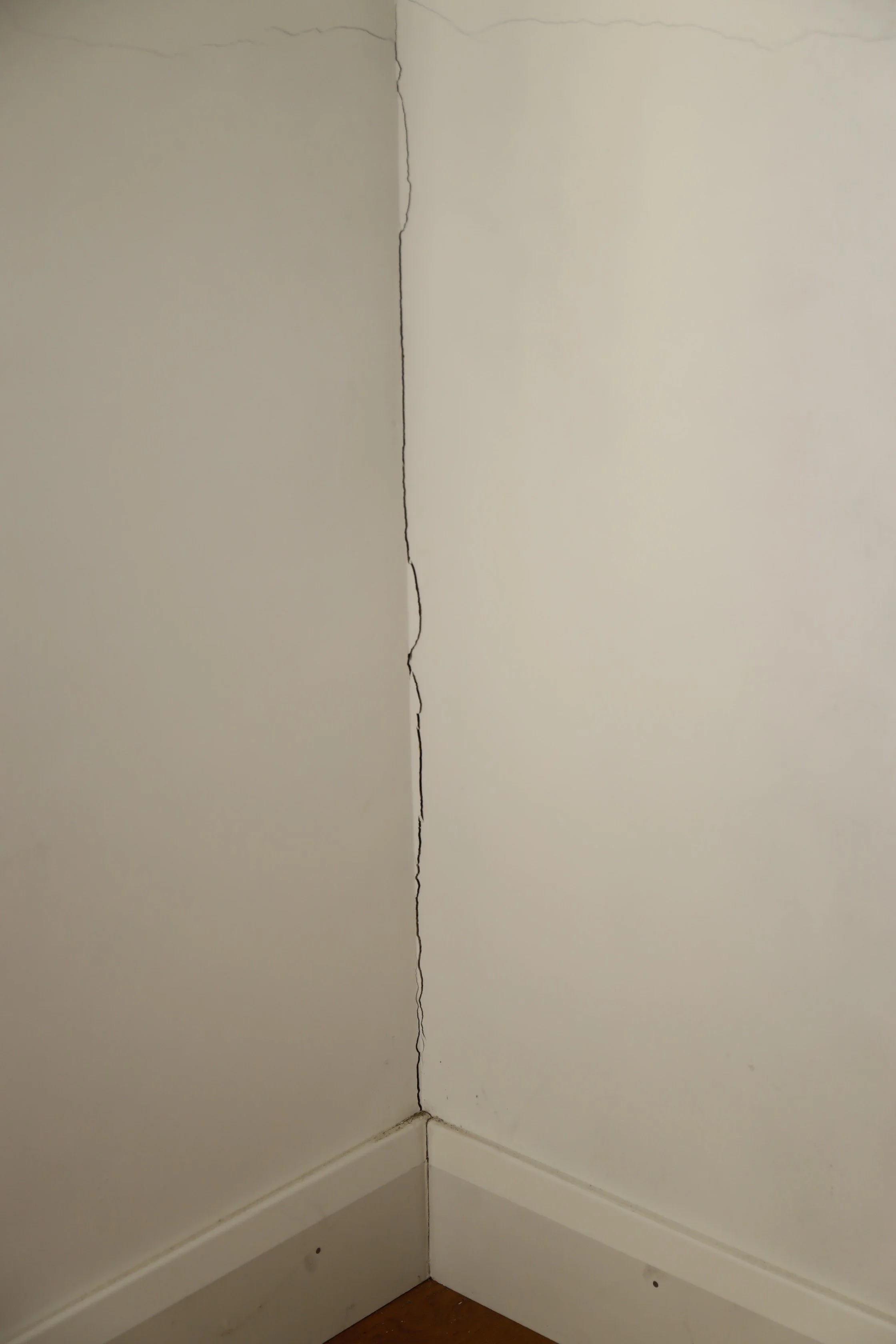

Within a few weeks of installation, the homeowners started to notice cracks in the walls - new cracks, that seemed to be growing slightly as the days passed. They contacted the installation company, and were advised this behaviour was normal, that the walls were simply settling. As the months passed, cracks continued growing, and new cracks continued forming. The installation company refused to acknlowedge any issue. The homeowners contacted Corcoran Consulting & Forensic Engineering for an independant evaluation of the issue, and to test the suitability of the foam that now lined the insides of their walls.

How did we analyse it?

Like anything involving concrete saws, extracting a sample of this foam from within the wall cavity was not easy. Square holes, approximately 250 x 250 mm, were cut into the concrete wall, revealing the pink spray-injected foam. The block of concrete and insulation was removed, and the inside examined. Large voids were observed, which are typically caused by a build up of gasses produced by the chemical reaction creating the foam.

The sample of foam was separated from the concrete, and returned to the CCFEng laboratories for “Dimensional Stability” testing, as discussed in our previous Case Study. It involves exposing the sample of foam to an elevated temperature and/or humidity for 48, and measuring the changes in length, width, and thickness of sample. and is conducted in accordance with a recognised international test stanadard, I.S. E.N. 1604. If the measured change in dimension is outside of the specified limit (typically 8%), we know there is a problem.

Separately, my client sought from the installation company a copy of the job card - a sort of receipt for the homeowner of the specific technical parameters around the installation procedure, such as pressure and temperature. This type of documentation is typical requirement to become an approved installer.

What was the resolution?

The dimensional stability testing resulted in an average change of thickness of 12.3%, well in excess of the specified limit. A review of the job card found the raw materials had not been heated sufficiently during the installation process, and the chemical reaction between the raw materials was slowed. This resulted in a build-up of gasses, as seen in the extracted sample, and a foam that hadn’t fully cured. A full Technical Report was prepared on the investigation and test results.

This Technical Report was shared with the installation company, who could not dispute the findings. The discussion turned to repairs, which are dense, technical, and ongoing with the raw material manufacturers.

If you deal with insulation in any form, as an installer, facade inspector, or even as a homeowner, and require expert, science-supported, evidence-based Expert Opinion, be sure to Contact Us today!