Materials Analysis in an Arc Flash Incident

What Happened?

Data Centres are popping up across the whole world, and Ireland is no exception, thanks in part to our mild climate. These energy intensive buildings require significant electrical systems to operate, which naturally require robust safety precautions. Any issues arising in the safety systems can have life-endangering consequences. One of the most dangerous is an arc flash event, in which huge amounts of energy is released by a sudden electrical discharge, often manifesting as an explosion.

One such incident occurred in a data centre on the outskirts of Dublin City. Thankfully, no-one was injured, but the electrical equipment involved was damaged. In the subsquent investigation, engineers observed unusual residues and discoloration across several metallic components around the locus of the accident. These were both upon the surface of copper conductor plates, and scattered across the ground in the vicinity of the unit.

To determine whether these deposits were the result of the arc event itself — or a contributing factor — samples were taken from the affected assembly and submitted for laboratory analysis.

How did we analyse it?

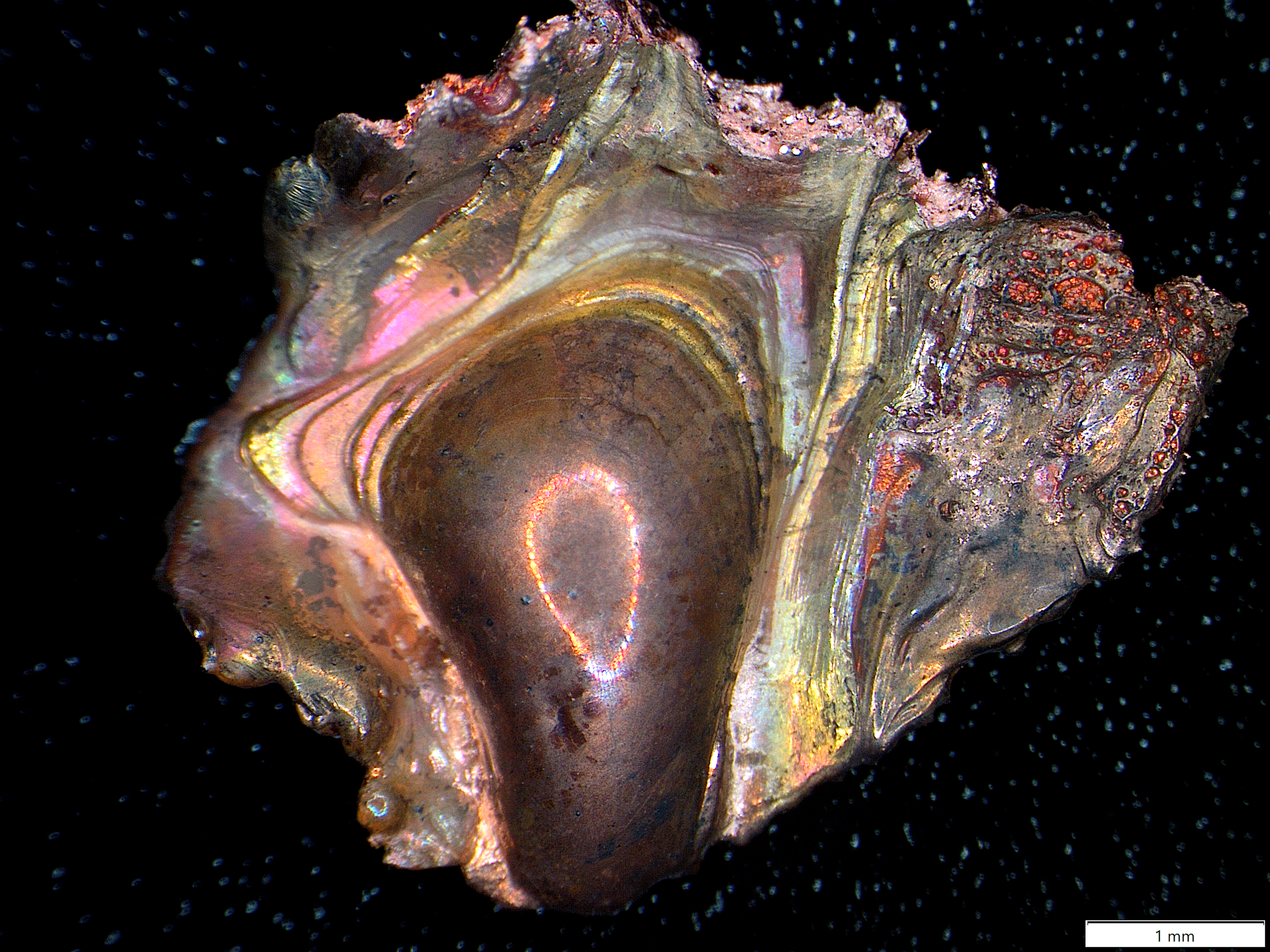

Some specimens had been fused to the copper substrate and had to be removed using specialist equipment (a chisel and hammer). Others had been recovered from the scene of the accident, including miscellaneous screws, welding rods, and abrasive papers. Eight specimens in total were selected. These were analysed using a combination of Scanning Electron Microscopy (SEM) and Energy Dispersive X-ray Spectroscopy (EDS), which determined the elemental composition of the specimens. The elemental compositions were then compared, to elucidate the cause of the arc flash accident.

What was the resolution?

In the analysis of the samples from the copper conductor, SEM-EDS analysis detected the presence of barium, a relatively uncommon element which is not typically found with copper. The analysis of the other miscellaneous specimens identified barium as a primary component for the weld wires found in the vicinity of the accident. It appeared that the conductive weld wire had become caught between the conductor plates, shorting them, and causing the arc flash incident.

I prepared an Expert Technical Report of my findings. My client had prepared a full post-installation procedure specification, which included cleaning steps to remove any debris. This had clearly not been followed, resulting in this unfortunate preventable accident.

Do you have unidentified materials to be analysis? Perhaps an accident which requires a closer look? For expert, science-supported, evidence-based Expert Opinion, be sure to Contact Us today!