Corrosion Testing & Analysis

Root Cause Analysis is a problem-solving process used to identify the core issue that caused an accident to occur. This process evaluates the issue as a whole, systematically identifying potential causes for the issue, gathering and reviewing all relevant information, and teasing out the series of cause-and-effect steps that led to the issue. This process often involves materials analysis of parts involved in the issue. For example, we might examine a bolt for signs of wear, a bracket for evidence of corrosion, or hard particulate within a paint film. The materials analysis provides additional information on the actual condition of the parts involved in the incident, and helps us capture an accurate image of all relevant parts.

Information Gathering

The first, and arguably most important step, is to gather all of the information relevant to the issue. As an outsider looking into a problem, there can be quite a lot of catching up to do - familiarising yourself with the proccesses and equipment involved, what materials are used, what are the goals and requirements, etc.

Materials Analysis

Sectioning of components, metallic, electronic, or otherwise, using automated cutting equipment.

Mounting of cut components in epoxy resin, and grinding and polishing to a scratch-free mirror finish

Cause-and-Effect Review

Advice and some testing in accordance with EN/ISO/ASTM standards, such as:

ISO 1461 - Hot dip galvanised coatings.

ISO 9223 - Corrosivity of atmospheres.

ASTM E112 - Determining average grain size.

EN 1604 - Dimensional stability of insulation foam.

ISO 2178 - Measurement of coating thickness on magnetic substrates.

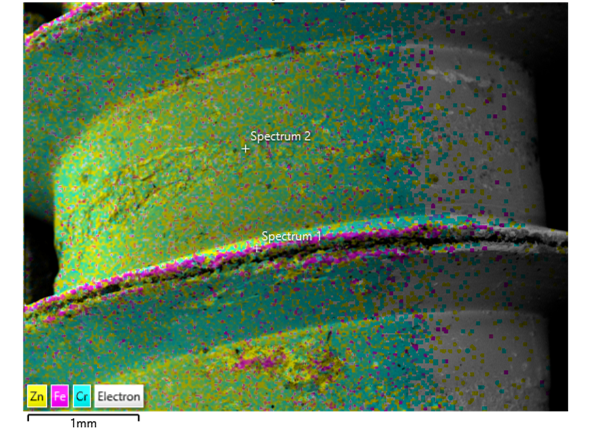

Corrosion testing, analysis, & advice

Measurement of rate of corrosion of metals.

Practical testing of corrosion resistance.

Analysis of corroded articles.

Advice on corrosion prevention.